Sikaflex 522 Caravan & Motorhome Adhesive Replaces 512 BG170

Sikaflex-522

Weathering resistant low emission multipurpose STP sealant

Sikaflex-522 is a low emission 1-component Silane Terminated Polymer (STP) sealant/adhesive. It has a high weathering and mold resistance. Sikaflex-522 meets highest EHS standards. It bonds well to a wide range of substrates with minimal pre-treatment.

High ageing and weathering resistant

High fungicidal resistance

Very low emission and odor

Important Notice:

Please note that the images of the product shown above are for illustrative purposes only.

While we strive to provide accurate representations, there might be slight differences between the product image and the actual product you receive. These variations could be due to lighting, individual screen settings, product enhancements, or minor design updates from the manufacturer.

We assure you that any discrepancies are minimal and will not affect the overall quality and functionality of the product.

If you have any questions or concerns, please feel free to contact our customer support team for further assistance at support@batsol.co.uk or phone us at 01752 656270.

At Batteries and Solar, your satisfaction is our top priority, and we are committed to providing the best shopping experience for you.

Thank you for choosing Batteries and Solar for your purchase.

Key Features

PRODUCT BENEFITS

High ageing and weathering resistant

High fungicidal resistance

Very low emission and odor

Bonds well to a wide variety of substrates without the need for special pre-treatment

High colour stability under UV

Isocyanate, solvent, phthalate and silicone-free

Meets hygiene requirements for ventilation and air-conditioning systems and units according VDI 6022 Blatt 1:2011-07

ISEGA certificate for foodstuff area usage

EC1+ certificate

Usage

Sikaflex-522 adheres well to a wide variety of substrates and is suitable for interior and exterior elastic sealing and bonding applications. It is suitable for applications in areas of air ventilation and incidental food contact. Suitable substrate materials include timber, glass, metals, metal primers and paint coatings (2-part systems), ceramic materials and plastics. Seek manufacturer€™s advice and perform tests on original substrates before using Sikaflex-522 on materials prone to stress cracking. This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be performed ensuring adhesion and material compatibility.

Specifications

Chemical base

Silane Terminated Polymer

Colour (CQP001-1)

White

Cure mechanism

Moisture-curing

Density (uncured)

1.4 kg/l

Non-sag properties

Good

Application temperature

5 ”€ 40 °C

Skin time (CQP019-1)

30 minutes A

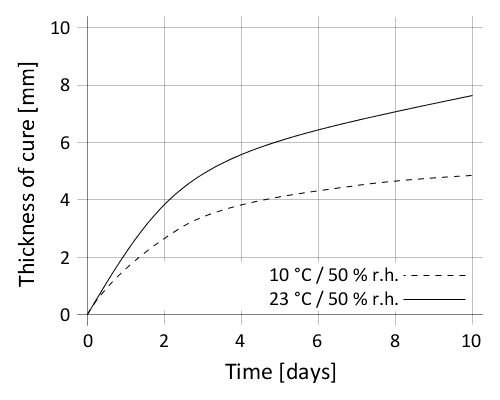

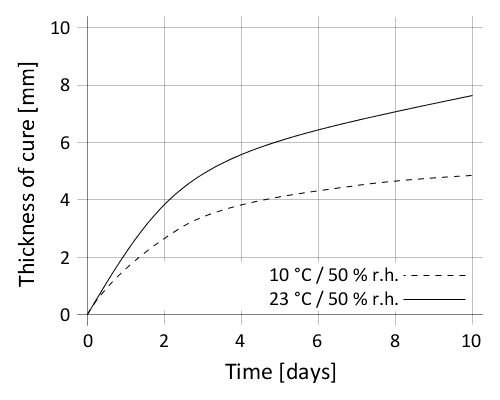

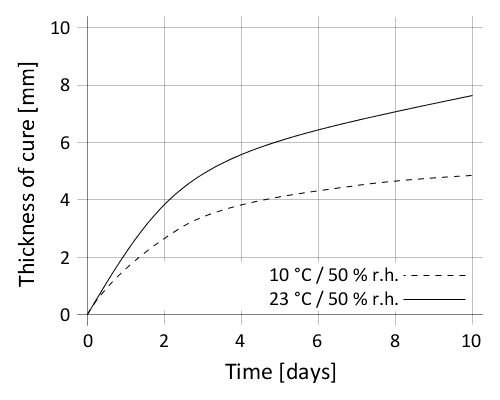

Curing speed (CQP049-1)

(see diagram)

Shrinkage (CQP014-1)

2 %

Shore A hardness (CQP023-1 / ISO 48-4)

40

Tensile strength (CQP036-1 / ISO 527)

1.8 MPa

Elongation at break (CQP036-1 / ISO 527)

400 %

Tear propagation resistance (CQP045-1 / ISO 34)

7.5 N/mm

Service temperature (CQP513-1)

4 hours

1 hour

-50 ”€ 90 °C

140 °C

150 °C

Shelf life

Unipack / Cartridge Drum

12 months B 9 months B

CQP = Corporate Quality Procedure

A) 23 °C / 50 % r.h.

B) storage below 25 °C

CURE MECHANISM

Sikaflex®-522 cures by reaction with atmospheric moisture. At low temperatures the water content of the air is generally lower and the curing reaction proceeds some-what slower (see diagram 1).

Diagram 1: Curing speed Sikaflex®-522

CHEMICAL RESISTANCE

Sikaflex®-522 is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents.

Diagram 1: Curing speed Sikaflex®-522

CHEMICAL RESISTANCE

Sikaflex®-522 is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents.

Attachments

Weathering resistant low emission multipurpose STP sealant

Sikaflex-522 is a low emission 1-component Silane Terminated Polymer (STP) sealant/adhesive. It has a high weathering and mold resistance. Sikaflex-522 meets highest EHS standards. It bonds well to a wide range of substrates with minimal pre-treatment.

High ageing and weathering resistant

High fungicidal resistance

Very low emission and odor

Important Notice:

Please note that the images of the product shown above are for illustrative purposes only.

While we strive to provide accurate representations, there might be slight differences between the product image and the actual product you receive. These variations could be due to lighting, individual screen settings, product enhancements, or minor design updates from the manufacturer.

We assure you that any discrepancies are minimal and will not affect the overall quality and functionality of the product.

If you have any questions or concerns, please feel free to contact our customer support team for further assistance at support@batsol.co.uk or phone us at 01752 656270.

At Batteries and Solar, your satisfaction is our top priority, and we are committed to providing the best shopping experience for you.

Thank you for choosing Batteries and Solar for your purchase.

Key Features

PRODUCT BENEFITS

High ageing and weathering resistant

High fungicidal resistance

Very low emission and odor

Bonds well to a wide variety of substrates without the need for special pre-treatment

High colour stability under UV

Isocyanate, solvent, phthalate and silicone-free

Meets hygiene requirements for ventilation and air-conditioning systems and units according VDI 6022 Blatt 1:2011-07

ISEGA certificate for foodstuff area usage

EC1+ certificate

Usage

Sikaflex-522 adheres well to a wide variety of substrates and is suitable for interior and exterior elastic sealing and bonding applications. It is suitable for applications in areas of air ventilation and incidental food contact. Suitable substrate materials include timber, glass, metals, metal primers and paint coatings (2-part systems), ceramic materials and plastics. Seek manufacturer€™s advice and perform tests on original substrates before using Sikaflex-522 on materials prone to stress cracking. This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be performed ensuring adhesion and material compatibility.

Specifications

Chemical base

Silane Terminated Polymer

Colour (CQP001-1)

White

Cure mechanism

Moisture-curing

Density (uncured)

1.4 kg/l

Non-sag properties

Good

Application temperature

5 ”€ 40 °C

Skin time (CQP019-1)

30 minutes A

Curing speed (CQP049-1)

(see diagram)

Shrinkage (CQP014-1)

2 %

Shore A hardness (CQP023-1 / ISO 48-4)

40

Tensile strength (CQP036-1 / ISO 527)

1.8 MPa

Elongation at break (CQP036-1 / ISO 527)

400 %

Tear propagation resistance (CQP045-1 / ISO 34)

7.5 N/mm

Service temperature (CQP513-1)

4 hours

1 hour

-50 ”€ 90 °C

140 °C

150 °C

Shelf life

Unipack / Cartridge Drum

12 months B 9 months B

CQP = Corporate Quality Procedure

A) 23 °C / 50 % r.h.

B) storage below 25 °C

CURE MECHANISM

Sikaflex®-522 cures by reaction with atmospheric moisture. At low temperatures the water content of the air is generally lower and the curing reaction proceeds some-what slower (see diagram 1).

Diagram 1: Curing speed Sikaflex®-522

CHEMICAL RESISTANCE

Sikaflex®-522 is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents.

Diagram 1: Curing speed Sikaflex®-522

CHEMICAL RESISTANCE

Sikaflex®-522 is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents.

Attachments

Chemical base

Silane Terminated Polymer

Colour (CQP001-1)

White

Cure mechanism

Moisture-curing

Density (uncured)

1.4 kg/l

Non-sag properties

Good

Application temperature

5 ”€ 40 °C

Skin time (CQP019-1)

30 minutes A

Curing speed (CQP049-1)

(see diagram)

Shrinkage (CQP014-1)

2 %

Shore A hardness (CQP023-1 / ISO 48-4)

40

Tensile strength (CQP036-1 / ISO 527)

1.8 MPa

Elongation at break (CQP036-1 / ISO 527)

400 %

Tear propagation resistance (CQP045-1 / ISO 34)

7.5 N/mm

Service temperature (CQP513-1)

4 hours

1 hour

-50 ”€ 90 °C

140 °C

150 °C

Shelf life

Unipack / Cartridge Drum

12 months B 9 months B

| CQP = Corporate Quality Procedure | A) 23 °C / 50 % r.h. |

B) storage below 25 °C

CURE MECHANISM

Sikaflex®-522 cures by reaction with atmospheric moisture. At low temperatures the water content of the air is generally lower and the curing reaction proceeds some-what slower (see diagram 1).

Diagram 1: Curing speed Sikaflex®-522

Diagram 1: Curing speed Sikaflex®-522

CHEMICAL RESISTANCE

Sikaflex®-522 is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents.

Attachments |

Internal Reference:

112185

Your Dynamic Snippet will be displayed here...

This message is displayed because youy did not provide both a filter and a template to use.